STAGE 4. WASHING THE SOIL

Separated from the large Embedding and released from the soil lumps sludge fed into the plant for cleaning and removal.

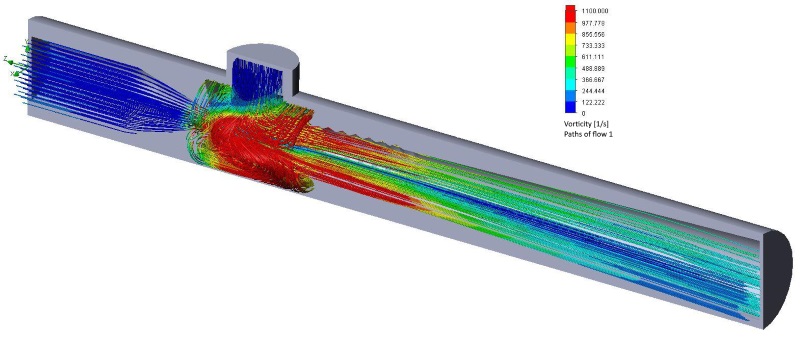

The sludge is washed using patented technology, inkjet geometry machine. The essence of the process is as follows:

The flow of recycled water of about 150 cub.m / h, tucked in the plant (shown on the conventional image left) creates a vacuum that sucks the sludge from the receptacle through the intake device in the upper nozzle of the jet device with a capacity of 5-20 cub.m / hour. In the unique geometry impact chamber located at the junction of the two streams, the speed of sludge particles increased hundreds times in short period of time, which leads to their numerous collisions, then the flow rate is reduced in a special diffuser and goes into the separation unit.

The solids separates on hydro cyclones of the separation unit, dewatered on vibrating screen, then washed clean soil is discharged outside the plant, and water-oil emulsion with silt goes into a working water treatment tank.